Weblog

Fri, 18 Apr 2008

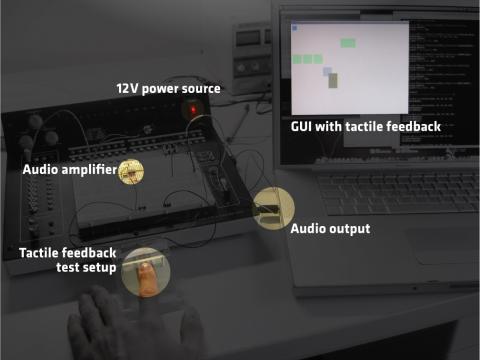

During the past month I've been refining the hardware part of my project. Here are some updates:

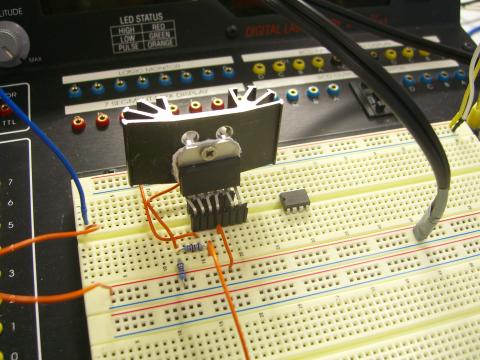

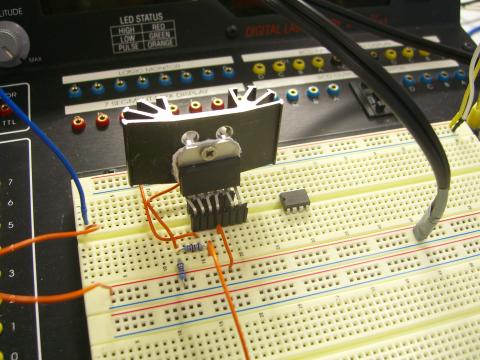

First of all, I had to buy a better amplifier. The previously used op-amp (ST L272) couldn't handle the required voltage, so I got a National Semiconductor LM3875 power amplifier that is able to handle voltages up to ±82 volts. In the current setup I'm using two 30V DC supplies that are connected in series in order to supply the power amplifier with +30V and -30V, respectively. The two chips are depicted in the photo, the big one on the left is the power-amp:

Because my actuators are very weak, I had to look for something light to actuate. I bought a cheap (maybe too cheap because it's not very accurate) Higgstec 9" 5-wire resistive touchscreen-overlay and built a wood housing for it to see whether this setup could work. I put a piezo actuator in each corner and lay the touchscreen-overlay on top. I found out that it works better when the overlay is supported by very small rubber-patches because the actuators can move more freely. The whole frame is put on top of a lying 19" monitor and the display is fit into the small frame through software scaling.

After I got this all working I re-made the frame with acrylic glass because it was quite thick before and thus too far away from the monitor. Also I took care of all the thin wires which could be easily torn off the actuators before. This was a very, very fiddly kind of work as I wired them around a bigger cable using two tweezers and a very calm hand …

Tue, 18 Mar 2008

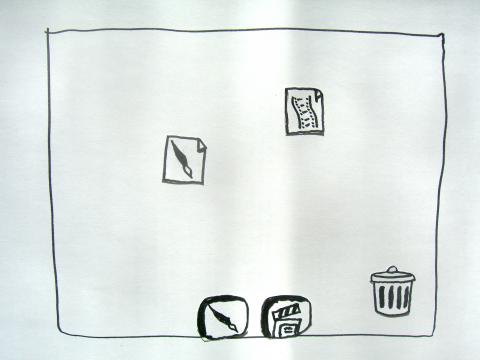

I'm currently thinking about ways to introduce a user to the tactile feedback setup. I'm planning to have several small sample programs that highlight different aspects of tactile feedback, therefore I need a way to switch between them. One way could be to use the desktop metaphor:

I know, I know, maybe the desktop metaphor isn't the way to go in finger operated systems, but at the moment I'm really not too opposed to using this because it allows the user to point to an object and handle it naturally. I will discuss this subject more in depth in a future post, so let's assume this is ok.

In this first animation the movie icon makes a short confirmation vibration when first touched. When dragged it makes a low sine vibration («smooth»). When it's dragged over the trash can it «shrieks» and makes a stronger vibration. There are also different hover stati for different targets: when the icon is dragged over the wrong application it doesn't confirm that it can accept the file, when it's over the movie application it shows through vibrations that it can be dropped here:

A further scenario that can be shown on the desktop is «click & hold» which in this case reveals a menu:

One last concept for today: grabbing. I define grabbing as clicking anywhere on the screen and then moving the finger to the target (still pressed on the screen). This way the target gets bigger, because you can click near it and then feel your way to it.

Tue, 18 Mar 2008

I see a lot of potential in using tactile feedback for video applications. E. g. when fast-forwarding in a video it's hard to tell how fast the video really moves and you move past the scene you're looking for a couple of times before you can stop the video at the right place. This problem can be solved by using special devices in the form of jog and shuttle controls, but this requires special hardware and it also limits the use of the hardware to the purpose it was originally designed. So I'm currently thinking of ways to use tactile feedback in video applications.

When discussing this with my fellow students they pointed me to the Lemur device by Cycling '74, a multi-touch screen that you can program to your likings. I could imagine such a device with tactile feedback to be a joy to use. Because the vibrational feedback works only on the whole screen, the screen probably should be smaller and different instruments should be on different screens. Say iPhone-sized :)

Fri, 14 Mar 2008

During the last week I have extended my test setup in several areas. I soldered the remaining three piezo actuators and built them into my housing to get more actuation power. I first tried this setup with a thin plastic layer over the actuators to see whether the vibrations would be transferred. This didn't really work, though, so I tried a small glass plate that I took from a picture frame which vibrates pretty well, even tough it's quite heavy (compared to the plastic layer). So I think I will have to use a touch screen that's as hard as possible.

To test my setup I wrote a Processing-program where I can move different kinds of interface items and have them make sounds in the following situations:

- If the item can be dragged it shows this by making a low, continuous sound when held

- If the item is dragged, it makes a «friction» sound

- If an item is clicked, it confirms this with a low sound

- If an item is released with the mouse inside, it confirms this with a click (if it's released outside, nothing happens)

- If an items border touches another items border, a clicking sound is made

- If you drag an item over another item (mouse within the concealed item) the concealed item can make various kinds of sound to indicate, whether you can drop the item you're holding here.

There are many more situations that can give feedback, but I will leave those to another post. I'll be doing some more research over the next week on how to use touch feedback specifically and will adapt my prototype accordingly.

What I found with this prototype is, that some sounds are too short or too high pitched and cannot be felt. A sine wave at 200 Hz can be felt very well, as can a snare-drum sound sample. A low volume sawtooth wave at 200 Hz can hardly be felt, but it's perfect at 50 Hz. I will try out different generated sounds and sound samples (like the OS X system sounds) to see how they work.

One big drawback with the current prototype is the sound the actuators are making (piezo elements are also used in loud speakers and microphones). I have to use earplugs to not get distracted by them and really feel the vibration and not think I feel it but in reality I only hear it.

Tue, 4 Mar 2008

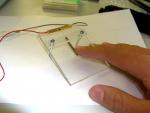

Today I soldered a second piezo actuator and built a housing for it. Because the actuator is very weak (0.13 Newton), this prototype has to be operated directly on the skin.

My next step will be to build some simple software sketches with Processing and try them on the prototype.

Mon, 3 Mar 2008

Today I soldered my first piezo actuator. Because the middle layer is very thin, I had to use a microscope. The rightmost photo (taken through the microscope) shows the dimensions of the piezo actuator: it's about 1mm thick and has a very thin brass layer between two piezo ceramic layers. That's where you're supposed to solder to…

Sun, 24 Feb 2008

My first week on the project was spent figuring out how to build my prototype. The piezo actuators needed are very expensive and difficult to use, but I found a good offer from Piezo Systems.

These actuators are probably not strong enough to create vibrations in a glass surface, but I think they're good enough to get started. Simple tactile experiments can also be done with the actuators directly on the skin, to see what it feels like. As these actuators need lots of voltage (±82V), I have to build an amplifier. That will be my next step.

Thu, 14 Feb 2008

My Bachelor's thesis will start on February 18th 2008.